Description:

This is a manufacturing plant, where water is purified and desalinated by forcing water through a membrane, typically known as a reverse osmosis process. Water produced by plant RO may be used for several purposes like desalination, wastewater treatment, and the reclamation of dissolved minerals.

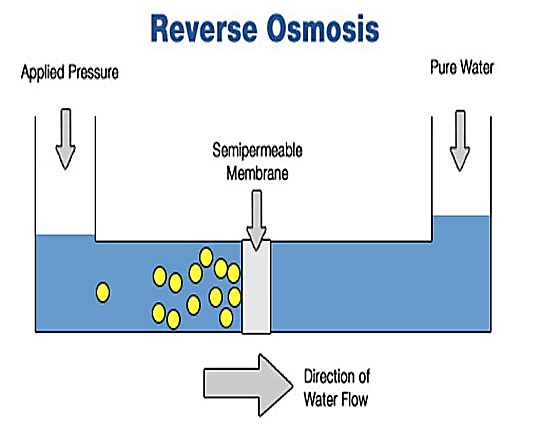

An average drinking water RO plant system requires six KW hours of electricity to desalinate one cubic meter of water. Reverse osmosis water plants requires a variety of pre-treatment techniques including softening, DE chlorination, and anti-scale treatment. Following pre-treatment, high levels of pressure send water through a semi-permeable membrane, which holds all contaminants except water.

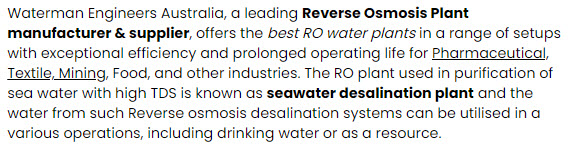

Working Principle

RO Plant or Reverse Osmosis Systems is working by using a high-pressure pump to increase the pressure on the salt side of the RO and force the water across the semipermeable RO membrane, leaving almost all of the dissolved salts left in the reject stream. This concludes the ro plant working principle.

Design:

We are an established manufacturer of reverse osmosis plants. And, To enhance the efficiency and life of the Reverse Osmosis plant, effective pretreatment of the feed water is required. Selection of the right pretreatment will maximize efficiency and membrane life by reducing:

- Fouling

- Scaling

- Membrane Degradation

plant design is consisting of:

Determining pretreatment requirement

If the feed water has traces of heavy metals, it is highly recommended to dose some chlorine to change the dissolved heavy metals to physical form, the media filter will filter most of it in a ro water purifier plant.

Reverse Osmosis Plant Selection of membrane:

Membrane elements are an important part of RO plants. The proteins (mostly polyamide) that makeup membrane elements vary depending on the ending clarity and intake water seawater or brackish water etc.

Configuration:

The conventionally following configuration is applied for the effective working of RO plant:

- Pre-Chlorination Dosing System

- Raw Water Storage Tank

- Feed Water Pump

- Multi-Layer or Media Filter

- Activated Carbon Filter

- Automatic Water Softener

- Antiscalant Chemical Dosing System

- Product Water Storage Tank

- Post-Chlorination Dosing System

- Product Water Pump (Re-pressurization)

- Product Water UV Sterilize

Advantages of

- Better tasting water and food

RO has the ability to remove 95 to 99% of total dissolved solids (TDS) in drinking water and improve the odor, appearance, and overall taste of water.

- Health benefits

Reverse Osmosis (RO) water filtration has proven to be most effective when it comes to removing impurities from water in an efficient and cost-effective manner.

- Simple maintenance

While some water filtration and purification systems are difficult to manage and time-consuming to maintain, RO systems are quite easy.

How RO Plant has replaced DEMINERALISATION PLANTS, DM PLANTS (RESIN BASED):

DM water can be produced by multiple stages of passage through ion exchange resins and zeolites till there is virtually nothing other than water left. As one of the renowned Multi effect evaporator manufacturers, this purified water may be used for boiler feed water in power stations but not for drinking but is a very expensive process for town water supplies.

As Reverse Osmosis plant manufacturer, the RO water is produced by a single pass of filtered water through an RO membrane. Due to leaks and slight imperfections, the membranes can contain up to about 1500 parts per million (0.15%) of assorted dissolved substances. That would be acceptable for drinking. RO plant requires power to run pressure pumps and fairly frequent replacement of membranes so is expensive but not as expensive as distillation or the full DM process. Moreover, as reverse osmosis plant exporters, we are proud of the high quality, robust design, long lifespan, fracture toughness, and damage tolerance of our products. As Reverse osmosis system manufacturer, the reverse osmosis water purification plant price depends on the requirement of clients, and the where it will be used. Also, as suppliers, we make sure that our customers receive items that meet their expectations and uphold the highest standards of quality.

RO Recovery:

RO recovery rate is influenced by the quality of the feed. The contaminants are generally inorganic salts and organics which

- raise the Osmotic Pressure

- foul the system’s membrane

The fewer TDS you have, the less applied pressure is required in order to push the water through the pores of the RO membranes. That is the reason BWRO can achieve up to 70-97% recovery (especially with new system configurations) and SWRO is limited to 35-45%.

SEAWATER DESALINATION WITH REVERSE OSMOSIS PLANT:

All Reverse Osmosis plants are basically Desalination Plants but desalination is being referred to sea water normally. As sea water has very high TDS requires very high pressure to force sea water through membranes which are different then brackish water membranes.

SEA WATER DESALINATION

Desalination of seawater, a process that transforms saltwater into freshwater, has emerged as a vital solution to address the global water scarcity crisis. With an increasing demand for freshwater due to population growth and climate change impacts, desalination presents a promising avenue to secure a reliable water supply.

The most common methods of sea water desalination include distillation, where heat is applied to vaporize water, leaving the salt behind; and reverse osmosis, which employs a semi-permeable membrane to filter out salt ions. While these methods offer high-quality freshwater, they come with energy and environmental challenges, as they require significant energy inputs and can harm marine ecosystems when brine is disposed back into the sea.

Innovations in desalination technology aim to mitigate these issues. Energy-efficient systems, such as forward osmosis and pressure-retarded osmosis, seek to reduce energy consumption. Additionally, advancements in membrane materials and designs enhance efficiency and durability, extending the lifespan of desalination plants.

Desalination also plays a crucial role in providing drinking water to arid coastal regions, supporting agriculture, and ensuring industrial processes have adequate water supplies. However, high costs associated with infrastructure, energy, and maintenance remain a concern, necessitating ongoing research to make the process more cost-effective and accessible.

Collaborative efforts between governments, industries, and researchers are essential to refine desalination technologies and optimize their environmental impact. By harnessing renewable energy sources, improving brine management practices, and developing more sustainable methods, sea water desalination can evolve into a vital tool for achieving water security in an increasingly water-stressed world.

Waterman engineers Australia RO plant for seawater desalination

Waterman Engineers in Australia has designed a Reverse Osmosis (RO) plant for seawater desalination, which offers several advantages over other desalination methods. Here are some key benefits of their RO plant:

Energy Efficiency:

Compared to other desalination techniques like thermal distillation, RO requires less energy. Waterman Engineers' RO plant utilizes advanced membrane technology, allowing it to operate at lower pressures and reduce overall energy consumption.

Environmental Impact:

RO generates less brine discharge compared to thermal methods, reducing the impact on marine ecosystems. This aligns with Australia's focus on environmental sustainability and conservation.

High Water Purity:

The RO process effectively removes salts, minerals, and impurities, producing high-quality freshwater that meets stringent drinking water standards. This reliability is crucial for providing safe and clean water to communities.

Modular Design:

Waterman Engineers' RO plant employs a modular design, allowing for scalability and flexibility. This is particularly advantageous for areas with varying water demands, as modules can be added or adjusted accordingly.

Reduced Footprint:

RO plants generally have a smaller physical footprint compared to thermal desalination plants, which often require extensive infrastructure for heating and cooling processes.

Quick Start-Up and Shutdown:

RO plants can be started and stopped relatively quickly, allowing for better responsiveness to changing water demands and emergencies.

Lower Chemical Usage:

Unlike some other desalination methods, RO requires fewer chemicals for operation and cleaning, minimizing chemical-related environmental concerns.

Consistency in Performance:

The RO process is less sensitive to feedwater quality fluctuations than other methods, ensuring a more consistent performance over time.

Cost-Effectiveness:

While initial investment costs can be significant, RO plants tend to have lower operational and maintenance costs in the long run compared to thermal methods.

Compatibility with Renewable Energy:

Australia's growing focus on renewable energy aligns well with RO's energy-efficient nature. RO plants can potentially be powered by renewable sources, further reducing their carbon footprint.

Water Recovery:

Modern RO systems are designed for high water recovery rates, meaning a larger proportion of seawater is converted into fresh water, reducing waste.

Advanced Monitoring and Control:

Waterman Engineers' RO plant likely incorporates sophisticated monitoring and control systems, enabling remote operation and optimization for maximum efficiency.

Waterman Engineers' choice of RO technology demonstrates a commitment to sustainable and efficient water solutions. By leveraging the advantages of RO, their desalination plant contributes to water security, environmental stewardship, and technological innovation in Australia and beyond.

Multiple Effect Distillation (MED) for seawater by Multi Effect Evaporator Manufacturer:

As sea water desalination plants by multi effect evaporator manufacturer requires very high pressure pumps in short energy consumption is very high in sea water reverse osmosis systems forced to research for alternative of reverse osmosis plants for seawater desalination found Multiple Effect Distillation very cost effective in terms of energy consumption but fixed capital investment is bit higher. In many cases Multiple Effect Distillation(MED) would be associated with Thermal Vapour Compression ( MED TVC), or Mechanical Vapour Compression (MED MVC). And, Waterman Engineers Australia reverse osmosis plant price is the most competitive in the industry. To know more about the reverse osmosis plant price, and its details, mail us at water@watermanaustralia.com

Frequently Asked Questions:

1. How does reverse osmosis (RO) work?

Reverse osmosis known as RO, is a cutting-edge water filtration technique. It is a membrane filtration technique that operates by applying pressure to water and pushing it past the minuscule holes of a membrane that is semi-permeable. When water passes through the finest semi-permeable membrane of our reverse osmosis plant, it is deionized and demineralized. Several pollutants and toxins are held within the water that passes through the membrane, which aids various businesses in processing safer and healthier water.

2. Does your RO plant require regular maintenance?

No, our Reverse Osmosis plant is expertly designed to operate for a very long time. Our semi-permeable membrane allows you to get the required outcomes without stressing about plant upkeep because to its low membrane degradation, high permeate recoveries, and resilience. The plant's architecture has been simplified to need less care from you while still giving you water of top quality.

3. Why are our RO Plants Unique?

We've already established a market position for our RO plants. This accomplishment can be due to their extraordinary efficacy in purifying muddy or saltwater water. Our solution is supported by three key pillars: advancement, expertise, and excellence. Our RO plants employ membrane technique to treat water for both consumption and industrial uses.

4. What distinguishes reverse osmosis from a water filter?

Reverse osmosis varies from standard filters, primarily in terms of filtering efficiency. Unlike RO, which features membrane filtration technique that eliminates dissolved impurities in addition to stubborn dirt, ordinary filters just simply remove insoluble grime and particulates.

5. What benefits does the industrial RO system offer?

Reverse osmosis is a dependable technology, which is why industrial RO water plants are immensely popular. Ionic salts, living and dormant viruses, microbes, organic compounds with a high molecular weight, and suspended particles are all removed. The system is entirely automated, and the water that is drawn from the plant is fit for human consumption.

6. Why reverse osmosis is used in a desalination plant?

Seawater is turned into drinkable water at a desalination plant. The technique, called reverse osmosis, is most frequently used, which includes exerting external pressure to drive seawater across membranes from a highly concentrated region to a low concentration area. Microscopic pores in the seawater membranes permit water particles to flow through while mostly excluding salt and many other pollutants, resulting in the discharge of pure water from the other end. Sea water desalination membrane has higher capacity of membrane with bit more smaller pore size than brackish water membrane and require more pressure than brackish water membrane.

7. What Benefits do Desalination Plants offer?

It can provide an endless, climatically independent, and consistent source of quality water, extending water resources far more than is possible from the water cycle. Where there is no native source of freshwater, it can offer drinking water. As it typically surpasses criteria for quality of water, seawater desalination plants can help alleviate strain on freshwater resources that originate from places that need protection. In middle eastern countries, small island countries, where water sources have gone well below desired level where bore well water is not available, desalination plants are blessings for potable water requirements.

8. What is the principle of REVERSE OSMOSIS (RO)?

Reverse osmosis (RO) is a water filtration technique that makes use of the fundamental osmosis principle, i.e. tendency of water molecules to pass through a membrane from a region of low salt concentration to a region of high salt concentration. Conversely, in a RO system, an external pressure (pressure greater than osmotic pressure) is applied to reverse the flow of water molecules through semipermeable membrane which blocks/retains the unwanted molecules and larger particles, yielding water with high purity.

9. What is the main part, heart of reverse osmosis system RO PLANTS?

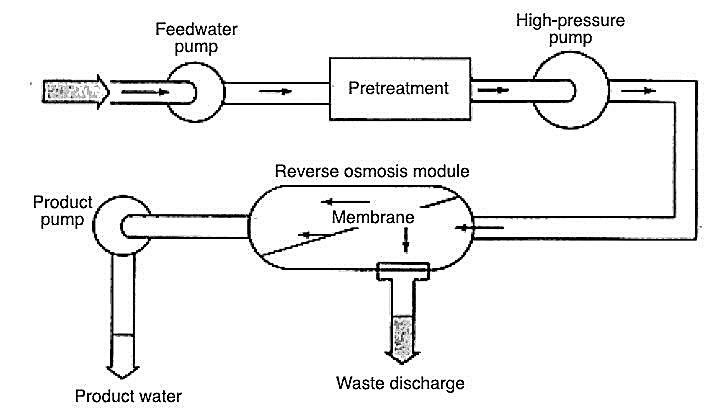

The RO module is the heart of the Reverse Osmosis system. The module comprises of the membrane/s employed for the purification process. The pore size of the employed membrane is responsible for purification/desalination/blocking of the unwanted particles.

10. How/what reverse osmosis membrane made out of?

RO membranes are made out of a flat membrane sheet which consists of three layers; a polysulfone layer, a barrier layer made of polyamide, and a polyester support base layer. The polysulfone layer serves as a reinforcement for the barrier layer, which removes salts, pollutants, germs, and viruses from water.

11. Type of reverse osmosis membrane/filters

The type of RO membrane is based on the different needs of the water filtration/purification application. The membranes are classified based on their pore size as; Micro-Filtration (MF), Ultra-Filtration (UF), Nano-Filtration (NF), and Reverse Osmosis (RO) membranes. A graphical illustration of what can flow through various membrane types is shown in the picture below.

RO membranes come in a variety of specifications to suit a range of requirements, including treatment of tap water (TW), Brackish Water (BW) and Sea Water (SW). For instance, a RO membrane that uses high pressure and requires a lot of energy to operate is not necessary to clean river water. The UF membrane would be the ideal membrane for such an application because it needs very little energy and will filter out even the smallest viruses and dirt particles in water that has a low salt content. River water that passes through a UF membrane is pure and suitable for drinking.

12. Is there membrane available for effluent treatment?

Yes, depending on the nature of effluent water and the quality of water required post filtration a schematic/system (single pass/double pass RO system) can be devised with combination of different types of membranes to achieve the required purity level.

13. What are the pre-treatment required for reverse osmosis membrane?

For a RO system to function properly and to avoid fouling, scaling, premature RO membrane failure, and frequent cleaning needs, proper pre-treatment employing both mechanical and chemical treatments is essential. Commonly employed RO pre-treatment process/solutions are listed below:

- Multi Media Filtration (MMF)

- Micro-Filtration (MF)

- Anti-Scaling/Scale Inhabitation

- Softening of Water by Ion Exchange

- Organics Removal by Activated Carbon

14. What are post treatment required for reverse osmosis membrane?

The RO product water is soft and slightly acidic (pH 5-6) with minimal alkalinity. Low-alkalinity water is hostile to metal and asbestos-cement pipes and absorbs calcium from pipes coated with mortar. Since they lack nutrients and have no flavour, they are not suited for distribution or drinking. Remineralization of the RO product water is therefore necessary to achieve the following goals:

- a minimum alkalinity of 80 mg/l as CaCO3

- a calcium carbonate precipitation potential (CCPP) of 3-10

- a positive Langelier Index (LSI) (0–0.5).

Appropriate treatment methods include:

- Carbon dioxide dosing followed by filtration via limestone and lime caustic dosage to elevate the pH over the saturation point

- Hydrated lime or calcite and carbon dioxide dosing; dosage of calcium chloride with sodium bicarbonate

15. Can reverse osmosis membrane remove arsenic?

Yes, Reverse Osmosis membranes are capable of removing arsenic. Nevertheless, pre-treatment can sometimes be necessary depending on the qualities of the raw water.

16. Can reverse osmosis remove heavy metal from water?

Yes, heavy metals including Arsenic (As), Chromium (Cr), Iron (Fe), Lead (Pb), and Mercury (Hg) can all be eliminated by reverse osmosis. Reverse osmosis (RO) filtration membranes have pores that are 0.1 nm in size, which is much smaller than the size of heavy metals. Heavy metals can be conveniently filtered out by RO systems due to their remarkably small pore size.

17. What are the limiting conditions for reverse osmosis systems RO systems?

Some of the limitations of RO system are mentioned as follows;

- Chlorine free water is required as RO feed for preventing membrane from spoiling.

- RO membranes are unable to filter out chlorine or other chemical pollutants. In a similar vein, they are unable to stop microbes or particles that are smaller than the membrane's hole sizes.

- Feed water quality should be maintained as per design specifications of the RO membrane. There is no one fit for all solution.

18. What are the different fouling can happen to reverse osmosis membrane?

Depending on the nature of fouling/foulants present in the feed stream, type of fouling is divided into four categories:

a) Inorganic fouling/scaling is the build-up of inorganic precipitates, such as metal hydroxides, on membrane surface or within pore structure.

b) Particle/colloids fouling happens when suspended solids and/or colloidal material stick to a membrane's surface or clogs the membrane's pores.

c) Microbial fouling sometimes also referred as biofouling is the growth of microbes, plants, algae, or other biological pollutants on or inside the pores and surfaces of filter membranes.

d) Organic fouling is defined as the collection of carbon-based material on a filtration membrane.

19. Precautionary measures to avoid reverse osmosis membrane fouling

A regular cleaning and maintenance regime can aid in preventing the accumulation of foulants on the membrane, such as;

- Careful selection of membrane material

- Choice of configuration

- Pre-treatment of raw feed water

- Process Optimization

- Control of Inorganic Salt Solubility

- Regular rinsing of RO membrane

- Use of a disinfectant

- Feed water temperature regulation

- Preventive maintenance

20. How much high pressure requires for reverse osmosis membranes?

A RO system requires a minimum of 30 psi to operate properly, but preferably 60 psi. In general, for fresh and brackish water, the pressure requirement is typically 2-17 bar (30-250 psi), whereas for seawater it is 40-70 bar (600-1000 psi).

21. In which industry reverse osmosis membrane can be used?

Reverse Osmosis is very efficient in treating nearly all types of water (brackish, surface and ground) for both large and small flows applications. A few examples of businesses that employs RO water are; Textile, Mining, Pharmaceutical, boiler feed water, food and beverage, metal finishing, and semiconductor production.

22. Is desalination different than reverse osmosis system?

Desalination is a separation technique used to reduce the dissolved salt content of very high saline water like sea water to a usable level. Whereas, RO is one of the separation techniques that can be employed for water desalination. Other notable desalination techniques are; Thermal multi stage flash distillation, Mechanical vapor compression, Electro dialysis, and Ion exchange.

23. Where are desalination plants being used?

Saudi Arabia, United States, Qatar, Bahrain, Kuwait, and the United Arab Emirates are nations chiefly relying on massive desalination of seawater for both domestic and industrial use. Furthermore, micro desalination facilities are also found in textile, leather, food industries, etc.

24. Working principle/ function of desalination plants SEA WATER DESALINATION PLANTS

A desalination plant works by reducing salt concentrations from brackish/seawater intended for human use or recovering salts from water supplies intended for industrial purposes. Desalination plants typically employ one or more of the following techniques for water treatment:

- Reverse Osmosis

- Mechanical Vapor Compression

- Thermal Multistage Flash Distillation

25. Comparison between desalination SEA WATER DESALINATION PLANTS and thermal distillation OF SEA WATER

Desalination is a separation technique used to reduce the dissolved salt content of saline water to a usable level. Whereas, thermal distillation is a process that involves changing saline water into vapor by means of thermal energy (heat). These vapours which are free from minerals, salt and other impurities are then collected and condensed, yielding high purity (> 99%) distilled water.

26. What is the pore size of reverse osmosis membrane?

Reverse osmosis membranes have a pore size ranging from 0.0001 micron (0.1 nm) to 0.001 micron (1 nm).

27. What is the pore size of desalination membranes?

Desalination membranes have a pore size ranging from 1.0 micron (1000 nm) to 2.0 micron (2000 nm).

28. What is the difference between Ion exchange resin and reverse osmosis membrane RO membrane?

Ion exchange is a physio-chemical process that selectively removes salts and contaminants by efficiently exchanging ions of similar electrical charges, whereas reverse osmosis is a physical method in which water is passed through a semi-permeable membrane against a concentration gradient by applying pressure.

29. Is Reverse Osmosis good for environment?

The leftover brine water of RO has just a slightly higher concentration of dissolved inorganics and is free from any sort of chemical/s. Thus, it makes it intrinsically safe for discharge and safe disposal. The carbon footprint of RO plant has just an impact of 2.1 - 3.6 kg CO2/m3 of treated water.

30. Difference between 1 and 2 stage REVERSE OSMOSIS, RO System?

In a single stage RO system, the feed water enters the RO system as one stream and exits the RO as either as permeate water or concentrate (or reject).

In a two-stage system the concentrate from the first RO system becomes the feed water to the second RO system. The permeate water collected from the first stage is combined with permeate water from the second stage. These additional stages aids in enhancing the recovery from the system.

31. What are some applications of REVERSE OSMOSIS, RO plant?

Typical applications of RO plant include:

- Purification of home drinking water

- Desalination of brackish/seawater water to produce drinking water.

- Recovery from wastewater

- Food and beverage processing

- Biomedical separation

- Industrial effluent/process water treatment

- Boiler feed water

32. What are basic components of REVERSE OSMOSIS RO system?

- Line Isolation Valves

- Pre-Filters

- Reverse Osmosis Membrane

- Post-Filters

- Auto Shutoff Valves

- Non-Return Valves

- Flow-Restrictor

- Storage Tank

- Faucet

- Drain Line